Safe use of high-temperature exhaust systems when transporting explosives

Recently, inspectors have flagged the design and location of high-temperature exhaust systems on newer models of heavy vehicles as a potential safety concern.

If you own or operate vehicles that transport explosives, you must ensure vehicles are suitable, and that your safety management system and security plan keep explosive loads safe and secure.

Impact of vehicle emission standards

Under the Australian Design Rules (ADRs), vehicle emission standards have been in place since the 1970s. Since then, standards for new vehicles have been tightened, requiring lower levels of particulate matter, nitrogen oxides and other emissions.

Since 2003, Australian standards for fuel have also been tightened, with sulphur levels for diesel fuel reducing from 500ppm to 10ppm.

Reductions in the amount of oxides of nitrogen (NOx) allowed in exhaust gases have led to the creation of additional processes within vehicle exhaust systems. As a result, combustion efficiency has reduced and the level of particulate matter or soot in exhaust emissions could potentially increase.

The potential danger

A regeneration (burn-off) process occurs when a certain amount of particulate matter accumulates in the on-board diesel particulate filter. The accumulated particulate matter can be burnt off by increasing the exhaust temperatures.

This temperature increase is achieved through heating coils, catalytic oxidisers and fuel burners. Such regeneration is conducted at very high temperatures (normal soot combustion requires a temperature over 600°C), though this can be reduced by fuel catalysts and other measures.

During this process, exhaust system components get extremely hot, exceeding 300°C.

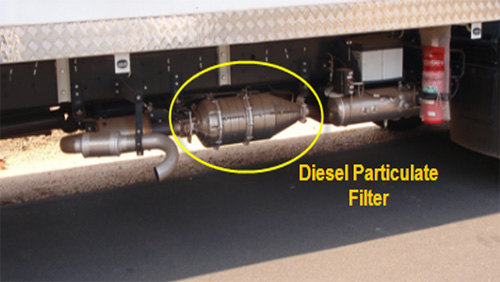

Figure 3: Exhaust system on a rigid truck with a diesel particulate filter fitted

In Figure 3, while the clearances appear adequate, the safety management system and driver training would need to address the potential for this system to start a fire.

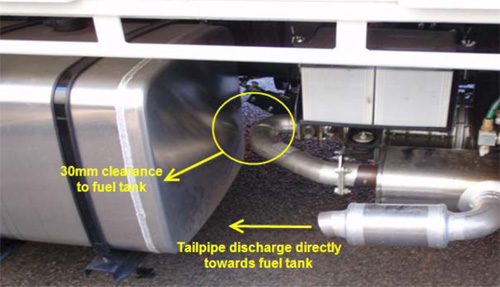

Figure 4: Exhaust system on a rigid truck

Figure 4 shows an exhaust system on a vehicle similar to that in Figure 3; however, the installation of an additional fuel tank creates a problem with spacing. In this instance, the original equipment manufacturer's body builder guide recommends a minimum clearance of 200mm between an exhaust component and a fuel tank. The heat-affected zone measured from the end of the tailpipe is 550mm, with the guide stating that no combustible components should be located in this zone.

As ADR requirements become more stringent, many more vehicles will need to be assessed for explosives transport and other applications where it's critical to address these potential ignition sources.

Any vehicles intended to transport explosives must be carefully assessed for their suitability.

The issues described above relate mainly to rigid vehicles fitted with explosives carry boxes, where the exhaust system runs under the horizontal fire screen and competes for underside space with many other components.

Any potential for diesel fuel to spill onto an exhaust component with temperatures in excess of 300°C is a risk, as is the potential for a fire.

The off-road operation of these vehicles is another concern, which should be covered in an organisation's safety management system, and reinforced through driver training and education. The risk of the exhaust system coming into contact with combustible materials creates the potential to start a fire under the vehicle. (Pulling off the road to give way to a wide load is a credible scenario in regional areas).

What you can do

- When assessing vehicles for suitability, consider the routing of exhaust systems and the proximity to other components, such as fuel tanks, electrical harnesses and cables, brake lines, hydraulic oil systems and fire screens, among other things.

- Do a robust risk assessment when ordering and fitting vehicles with aftermarket options and accessories. Refer to the original manufacturer's specifications for minimum separation distances, heat shield panels and general precautions on the exhaust system.

- Ensure that drivers' education and training adequately cover the risk posed by high temperature exhaust systems.