Managing risk in supply chains

By identifying key business activities that could be affected by disruptions to your supply chain, you can prepare a plan of action with a focus on your bottom line.

This resource looks at steps in supply chains, explores possible risks and links to the business continuity plan to manage these risks.

Definition of supply chain

A supply chain is a network of individuals and companies that produce and deliver a product or service to a consumer.

Supply chains are important to keep shelves stocked and items available for trade. Any disruption in the supply chain can cause problems in providing goods and services to your customers on time and within budget.

To manage risk in supply chains:

- identify supply chain risks within your business

- identify what is within your control or outside your control

- understand the impact on your business if there are disruptions

- develop a risk management plan to account for disruptions.

Why it's important to check your supply chain

When one element of your supply chain fails to deliver their product or service to the next business in the chain, the entire supply chain can be disrupted.

This can result in:

- delays

- reduced revenues

- inflated costs

- disruptions to your production or continuity of service

- damaged business reputation and customer confidence from delays, quality or ethical issues.

A business with a resilient and responsive supply chain has a competitive advantage over other businesses that do not.

Identify your supply chain

There are many steps and processes involved in developing goods and services.

A supply chain may include the following:

- individuals, businesses, and organisations that make products, components or raw materials (e.g. beekeepers produce honey which may be marketed by a beekeeper's cooperative to a larger company)

- businesses that produce packaging materials (e.g. boxes, bottles)

- logistics and/or transport businesses that transport the raw or manufactured products (e.g. tankers, goods trucks)

- businesses that supply IT software (e.g. online shopping portals, customer relationship databases, logistics, project management, telephones)

- businesses that provide marketing services (e.g. design, labels, online and traditional marketing)

- businesses that fill packaging materials (e.g. bottling lines)

- businesses that purchase, distribute, or sell the product (e.g. wholesalers, distributors, retail, and online retail shops).

Preparing for supply chain disruptions

The best way to manage a supply chain disruption is to prepare for it in advance.

A business impact analysis helps prepare your business for the impact of a supply chain disruption.

A business impact analysis:

- identifies your key business processes, procedures and standards

- examines key activities and resources you need to operate your business

- assesses how these would be affected by supply chain interruptions highlighted in your risk management plan.

A business impact analysis is part of a business continuity plan.

Download the business continuity plan template

This template includes 2 sections:

- risk management plan

- business impact analysis.

Use this page to consider your risk of a supply chain disruption, then complete the 2 sections of the template.

Download the business continuity planning template.

The level of impact on your business would depend on the severity and length of the disruption, but significant disruptions are likely to have a financial impact.

Completing a business impact analysis allows you to consider how a supply chain disruption would affect business activities, including financial management, and help to identify the ways you might prevent, or minimise the impact.

Case study: Key asset failure

If vital machinery breaks down and disrupts production, the impacts on various business activities could include the need to:

- focus resources on fixing the problem

- reduce or reallocate staff from the production area

- contact suppliers and let them know

- contact your downstream customers

- manage your inventory of raw materials and finished goods

- review orders and purchasing

- review the impact on sales, revenue and cashflow

- increase marketing activities to improve customer relations and business reputation.

Risks around your supply chain are either within your own control, or outside your control. Developing and reviewing your risk management and analysing the business impact as part of your business continuity plan ensures your business is prepared for any potential business disruptions.

Types of supply chain risks and potential mitigation

While supply chain risk may seem straightforward, it can be easy to overlook potential risk areas. There may be several ways to prepare for a supplier disruption but often, sourcing an alternate supplier may be the best solution.

Consider these types of supply chain risks and their possible risk preparation or reduction strategies.

Human resources

-

- Train internal staff in different roles as part of a development program

- Recruit staff with the skills you need (or have potential to learn the role or activity)

-

- Meet with the supplier and establish relationship with new key account holder

- Assess the change and consider exploring new supplier options

-

- Source alternative local suppliers

- Consider overseas suppliers if the risk is widespread and ongoing

Product, and packaging materials

-

- Use alternative packaging

- Increase sales in other product lines

- Seek and engage an alternative supplier

-

- Source local or national suppliers

Logistics delays

-

- Source alternative logistics from other countries or states

- Increase order volumes and local stock holding

- Check if covered by business insurance

Decrease in standards

-

- Check all products supplied

- Raise issues with suppliers and clarify standards

- Increase quality assurance checks

- Source potential alternative suppliers

Insolvency and bankruptcy

-

- Communicate with customers

- Explore the opportunity to buy any remaining inventory from the supplier

- Seek alternative suppliers

Manufacturing risks

-

- Check and service equipment regularly

- Check with other businesses to borrow or lease equipment

- Consider purchasing backup equipment for critical tasks

- Consider changing the way something is made as a short term workaround

With any supplier-related risks, knowing your suppliers and reducing reliance on a sole provider can help to reduce impacts on your business.

Also consider...

- Learn how to write a business continuity plan.

- Find out more about identifying and managing business risk.

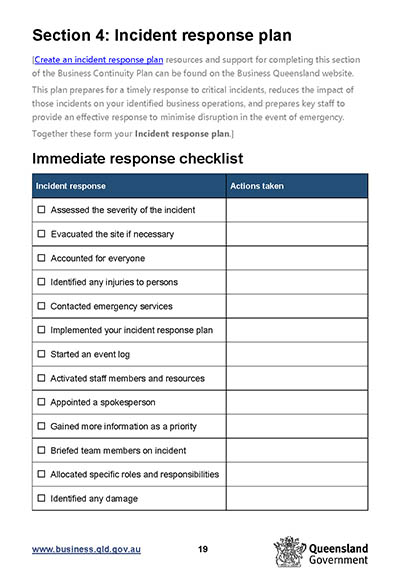

- Prepare or update your incident response plan.

- Read about managing IT risk.